In the vast realm of car care, valve cover gaskets stir quite the chatter. Reuse them? Some shudder at the thought, envisioning engine calamities. A tribe of skilled mechanics and DIY enthusiasts have repurposed and rejoiced.

What drives this split? Penny-pinching? Or the thrill of stretching every part’s lifespan? Delving into this gasket saga, we’ll sift fact from fiction. Whether you’re a garage guru or just dipping your toes, let’s embark on this riveting ride together.

The Science Behind Valve Cover Gaskets

Material Composition: Why It Matters

Ever wondered what makes those valve cover gaskets tick? Well, it’s all about the material magic. They can be crafted from various stuff, such as cork, rubber, or even good old plastic. Each of them brings its bag of tricks to the table.

Rubber Gaskets: Picture these as the flexible acrobats of the gasket world. As long as they stay limber and not brittle, they’re like the ninja warriors of sealing. An all-arounder that bends, flexes, and conquers temperature changes!

Cork Gaskets: It is the natural wizard in the gang. It’s got that sealing mojo but tends to wear out quicker than rubber. Cork gaskets are one-shot wonders, not recommended for repeat use.

Plastic Gaskets: The rare breed. Plastic gaskets are the cool secret agents, used in specific missions. They’re rigid, which can be a pro or a con, depending on the engine’s battle plan.

And here’s the kicker: Its performance is directly affected by the material you choose. Rubber may cost you a bit more, but it can be your trusty sidekick for the long haul.

The Lifespan of a Valve Cover Gasket

Hold onto your hats, because the lifespan of a valve cover gasket is a rollercoaster ride-through material, engine conditions, and some good old-fashioned TLC. It’s the same as a soap opera of rubber, cork, and plastic.

Rubber gaskets, when pampered, can take you on a multi-year journey. This journey can be cut short by wild temperature swings, dirt, and contaminants. That’s why it’s crucial to keep an eye on them during routine check-ups.

The Great Debate: To Reuse or Not to Reuse

Is it better to stick with your trusted old gasket or replace it with a new one? It’s a debate that has gearheads and grease monkeys locked in an eternal struggle.

Pros and Cons of Reusing Valve Cover Gaskets

Pros:

Saving Your Green: Reusing a gasket might be your ticket to financial freedom. A fresh gasket can cost a pretty penny, and if your old one’s still got some swagger, it’s similar to finding money in your pocket.

Ecologist Vibes: Going green is all the rage. Reusing it means less junk in the landfill, and Mother Nature gives you a high-five for it.

Rubber Resilience: If your gasket is rubber and still has some bounce in its step, it can usually handle an encore without breaking a sweat.

Cons:

Leak Roulette: There’s a chance your reused gasket might not seal the deal like a fresh one. That could mean oil on the move and an oil-slicked driveway.

Cork Conundrum: Cork gaskets are rockstars who burn out fast. They rarely survive a second tour.

Peace of Mind: Some people sleep better knowing their car has a brand-new gasket under the hood.

Proper Maintenance for Extended Gasket Life

Signs Your Valve Cover Gasket Needs Replacement

Ever wonder how to tell if your valve cover gasket is throwing in the towel? We’ve got your back with these telltale signs:

1. Oil Leaks Galore: Your gasket’s having a field day with oil leakage like it’s hosting a never-ending oil party right around the valve cover edges.

2. Engine Misfires Alert: It’s not just oil leaks; it’s the oil sneaking into the spark plug wells, causing engine misfires. Sparks should fly in your love life, not your engine!

3. Smoke Signals: If your engine’s suddenly puffing out smoke, it’s not preparing for a papal conclave. It’s probably due to oil dripping onto the exhaust manifold. Smoke on the road is no joke.

4. Unexpected Oil Scent: If your cabin suddenly smells like a garage, and you’re not in a garage, it’s likely the gasket’s having a meltdown, and you’re getting a nose full of burning oil. Not the kind of aromatherapy you were looking for, right?

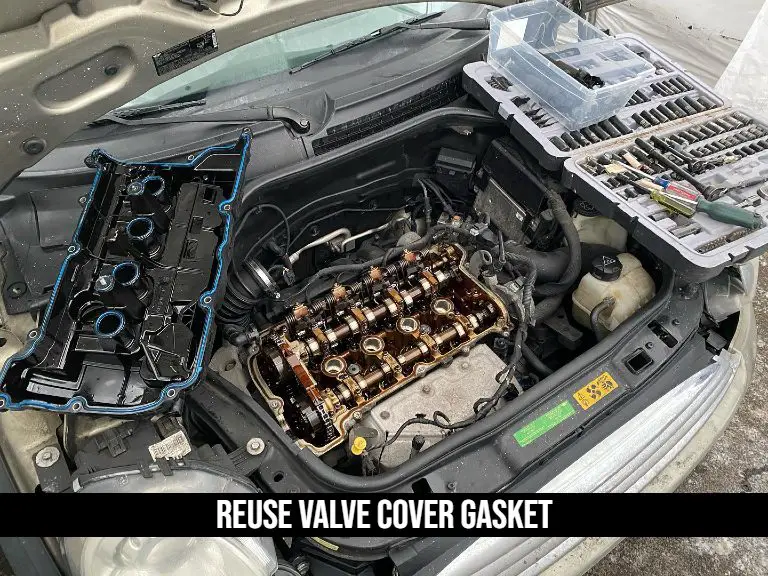

Cleaning and Preparing for Reuse

So, you’ve decided to give your old gasket a second chance at life? Wise choice! But remember, proper cleaning and prep are the secret ingredients. Here’s the scoop:

1. Material Inspection: It comes in all types, including rubber, cork, and plastic. If your rubber gasket isn’t as brittle as your humor in the morning, it might be worth a second shot. Cork-based gaskets, though, are like one-hit wonders; they usually need replacement.

2. Scrub-A-Dub: Before you rekindle the gasket romance, make sure to wash off any oily remnants or debris. A squeaky-clean piece promises a solid resealing job.

3. Sherlock Holmes Mode: Putting on your detective hat, examine it for any cracks, tears, or ‘We’ve been through a tough time’ marks. Even minor damages can lead to future leaks, and we don’t want that.

4. The Art of Reinstallation: If you’re giving your gasket a second chance, make sure it knows it’s loved. Place it correctly, ensuring it’s not sitting crooked. And if things get slippery, a dab of gasket sealant might be the wingman it needs for a successful comeback.

Innovations in Valve Cover Gasket Technology

The automotive realm is a playground for perpetual innovation, where every auto part dances to the rhythm of research and development. Enter the unsung hero, the valve cover gasket, a component that’s been quietly transforming itself.

The Shift to Sustainable and Durable Materials

Valve cover gaskets, traditionally woven from materials like cork and rubber, have gotten a serious upgrade. They’ve traded their old-school attire for new-age, high-tech threads.

The picture they are made of futuristic rubber blends that scoff at wear and tear. These super-gaskets aren’t just durable; they’re long-lasting, which means less frequent replacements and money saved for car owners.

But it’s not just about toughening up. The automotive world’s going green. Sustainability is the name of the game. Each part, including the humble valve cover gasket, gets scrutinized for its environmental impact.

Opting for recyclable or environment-friendly materials is similar to taking a step toward a cleaner, greener automotive future.

Future Trends in Gasket Production

Peering into the gasket’s future is the same as watching a sci-fi movie. Smart ones with built-in sensors that give you a heads-up when they’re ready to retire or when there’s a potential leak.

Imagine how that could transform car maintenance. No more guessing; just pure preventative action.

And then there’s the great material quest. While rubber and cork have been the stars of the show, researchers are digging for the next big thing. They’re looking for materials that can thrive under extreme conditions.

It’s like finding the superhero of gaskets, most suitable for high-performance rides or those that brave harsh terrains.

DIY Guide: Reusing Your Valve Cover Gasket

Step-by-Step Process for Safe Reuse

1. Inspect the Gasket: Examine the valve cover gasket closely. Look for wrinkles, hardening, or any signs of wear and tear.

2. Clean the Gasket: Remove any old oil and debris from it.

3. Reinstall the Gasket: Place the gasket back, ensuring it fits snugly.

4. Tighten the Valve Cover: Make sure the valve cover is tightened properly.

5. Start the Engine: Turn on your car and let the engine run.

6. Check for Leaks: After the engine is running, inspect its area for any oil leaks.

7. Monitor Regularly: Keep an eye on its condition over time to ensure its longevity.

Tools and Precautions for the DIY Enthusiast

For the DIY champs, the right tools are your sidekicks. A torque wrench, a gasket scraper, and some cleaning goodies are your trusty allies. No roughhousing with that gasket!

If needed, do some high-quality gasket sealant. Safety’s no joke; don your gloves, and let the fresh air in. Reusing them can be a smart move, but if you’re not sure, just go for a new one. Better safe than sorry, right?

Environmental and Economic Impacts

The Environmental Benefits of Reusing Gaskets

Every time a valve cover gasket is discarded, it contributes to the growing problem of automotive waste. This waste not only occupies space in landfills but also takes a considerable amount of time to degrade, especially if made from non-biodegradable materials.

By reusing them, we can significantly reduce this waste. Furthermore, the production of new gaskets requires resources and energy. Every step in the manufacturing process has an impact on the environment, from the extraction of raw materials to the manufacturing process itself.

We can reduce the environmental impact of gaskets by reusing them instead of buying new ones.

Moreover, certain gaskets, especially those made of rubber, can be reused if they are not brittle.

This not only conserves the material but also reduces the need for new production, further minimizing environmental harm.

Savings and Cost Implications for Car Owners

From an economic standpoint, reusing them can lead to significant savings for car owners. A new gasket can cost around thirty dollars, depending on the engine type and brand.

If the existing one, especially those made of rubber, is in good condition, it can be reused, saving the cost of purchasing a new one. Over time, such savings can accumulate, especially for individuals who frequently engage in DIY automotive maintenance.

Further, by reusing them, car owners can also avoid potential price hikes or shortages in the market. In times of economic fluctuations or supply chain disruptions, having the option to reuse can prove to be both economically wise and practical.

Beyond Cars: Reusing Gaskets in Other Machines

Industrial Applications and Reusability

Gaskets, particularly valve covers, are not exclusive to the automotive world. In various industries, these sealing agents play a pivotal role in ensuring machinery operates without leaks.

For instance, in the manufacturing sector, they are used in heavy machinery to prevent the escape of fluids, ensuring smooth operations. The aerospace industry also relies on high-quality gaskets to ensure the integrity of aircraft engines. The question then arises: can they be reused in such critical applications?

The answer varies. In some industries, the high stakes involved mean that they are replaced as a matter of routine, ensuring the utmost safety and efficiency.

However, in others, especially where the operational pressures and temperatures are lower, they can be inspected and reused if they meet stringent criteria.

The key lies in understanding the specific requirements of each application and the condition of the gasket in question.

Lessons from Other Industries: Best Practices

While the automotive sector has its unique challenges and standards, there’s much to learn from how other industries approach the issue of gasket reuse. For instance, in the maritime industry, where machinery operates in a saline environment, they are often subjected to conditions that can hasten wear.

Yet, with regular inspections and maintenance, some types of them can be reused, extending their lifecycle and reducing waste.

Another lesson comes from the world of electronics. Here, they are used to seal casings and prevent the ingress of dust and moisture. Given the lower operational pressures, these gaskets can often be reused multiple times, provided they remain undamaged and retain their elasticity.